Vacuumcoating is widely used in industry. During the evaporation process, under the high heat of the evaporation source, when the film running speed is less than a certain value, it is easy to fuse, the speed is faster and the coating thickness cannot meet the requirements.

The purpose is to provide a new vacuum coating machine, which can make the substrate effectively increase the thickness of the coating metal without being melted down at too low speed.

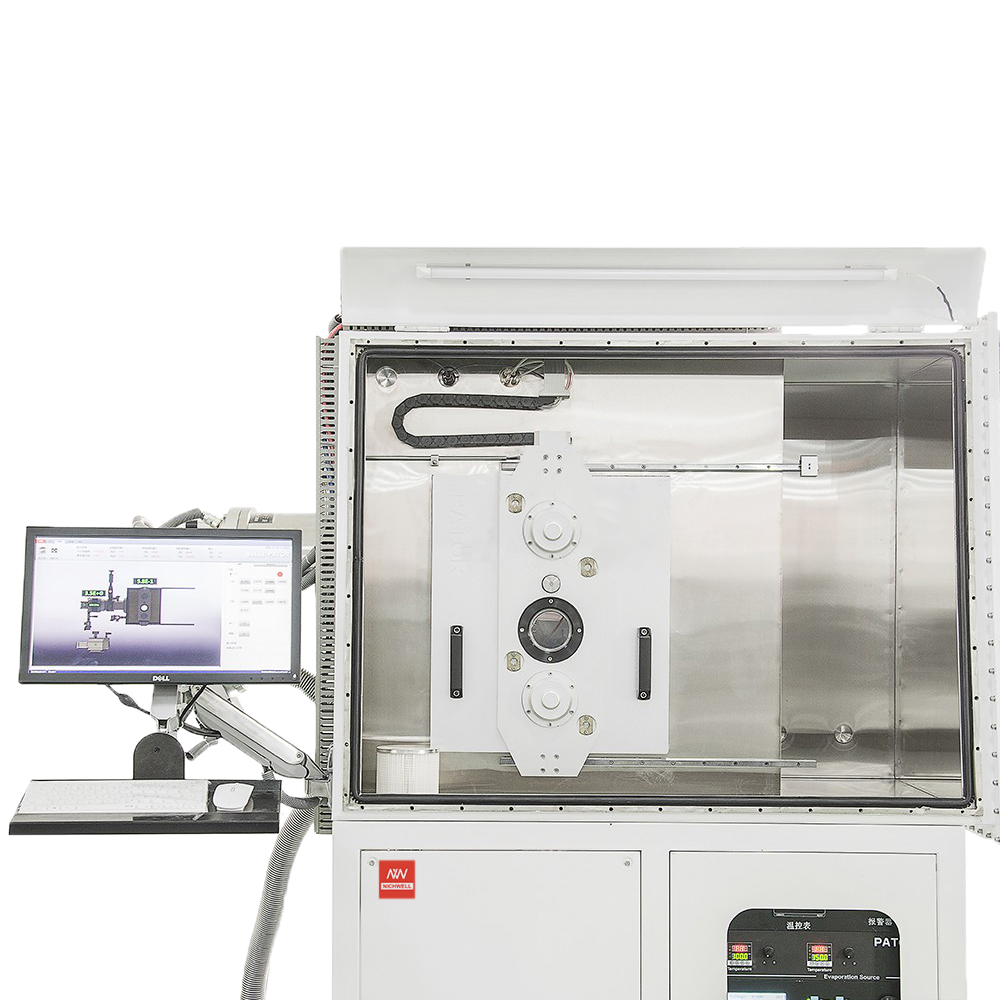

An integrated glove box vapor deposition machine, this system is an integration of a vacuum coating system and a glove box system. It can complete thin film evaporation in a high vacuum evaporation chamber, and carry out samples in a high purity inert gas atmosphere, storage, preparation and testing of samples after evaporation.

The combination of evaporation coating and glove box realizes the fully enclosed production of evaporation, packaging, and testing processes, so that the entire film growth and device preparation process is highly integrated in a complete controllable environment atmosphere system, eliminating the organic large area circuit preparation process The influence of unstable factors in the atmospheric environment guarantees the preparation of high-performance, large-area organic optoelectronic devices and circuits.

Your email address cannot be published. Required fields are marked*

No comments