Glove box accesories---VPL Oil Mist Filter

The Laboratory Glovebox Oil Mist Filter is a filter designed for laboratory environments to remove oil mists and particles generated inside gloveboxes. Laboratory gloveboxes are commonly used for working with sensitive samples, manipulating toxic substances or experiments with biosafety requirements. Oil mist filters help keep the air inside gloveboxes clean and prevent contaminants from spreading into the laboratory environment.

Laboratory glovebox oil mist filters work similarly to other oil mist filters and consist of two main steps: trapping and filtration:

Capture: When experimental operations result in oil mist inside the glove box, the oil droplets are captured by the filter, usually by one or more layers of fibrous material surface adsorption of oil droplets. These materials have a high surface area and small pore size to effectively capture oil mist particles.

Filtration: The captured oil droplets are further filtered to ensure more efficient oil mist removal. The filtration medium can be activated carbon, HEPA (High Efficiency Particulate Air) filters and other materials to adsorb and filter the oil mist, thus purifying the air inside the glove box.

VPL Oil Mist Filter is a filter designed for industrial machinery and other equipment to remove liquid oil mist and solid particles generated by machine operation. These oil mist and particles will affect the normal operation of machinery and equipment, and may cause pollution and harm to the environment of the production plant.VPL oil mist filter adopts advanced materials and technology, which can efficiently remove the oil mist and particles, and protect the production environment and machinery and equipment.

The working principle of VPL oil mist filters is based on wet filtration technology and consists of three main steps:

Capture: When mechanical equipment is in operation, liquid oil mist and solid particles enter the VPL oil mist filter through the air inlet. An inlet deflector inside the filter traps the deposited liquid oil droplets and particles in the fog core collector at the center of the filter.

Separation: Inside the fog core collector, the oil droplets and particles come into contact with water and are adsorbed by the water particles. The oil droplets and particles are then deposited in a settling tank at the bottom of the filter.

Purification: By circulating and filtering the water inside the filter, the contaminants in the settling pool are effectively removed, keeping the air inside the VPL Oil Mist Filter clean.

The advantage of VPL oil mist filter is that it can effectively remove oil mist and particles generated by mechanical equipment under different working conditions such as high temperature and high pressure, low temperature and low pressure. In addition, the VPL oil mist filter is characterized by excellent materials, advanced design and simple operation, which makes it easy to install and maintain, reduces the cost of use and extends the service life of the filter.

The selection of a laboratory glove box oil mist filter should be based on laboratory operational needs and safety requirements. Some filters provide additional protection, such as adsorption filtration for specific gases or hazardous substances. In addition, changing or cleaning the filter on a regular basis is a critical step in maintaining its filtration effectiveness.

glove box aparts---Foot Pedal

Gloveboxes are typically designed to be opened and closed by means of a foot pedal. A foot pedal is an operating device that is connected to the internal mechanics of the glove box and is used to open or close the glove box door by using your foot to step on or off.

Here is how a basic glove box foot pedal works:

Door control system connection: the foot pedal is connected to the glove box door control system. The movement of the foot pedal is usually translated into an opening or closing action of the glove box door by means of a linkage, chain or other mechanical device.

OPENING ACTION: When the foot pedal is pressed down, a mechanical device such as a linkage or chain transmits force to the glove box control system to open the door. This can be accomplished by pushing on the door latch or releasing the door latching mechanism.

CLOSING ACTION: When the foot is removed from the pedal, a mechanical device such as a linkage or chain will cause the glove box control system to close the door. This may involve putting the door latch or latching mechanism back into place to ensure that the door closes tightly.

The glove box foot pedal is designed to facilitate the user's ability to keep the glove box clean and operationally flexible without having to touch or operate the glove box door with their hands. The foot pedal is typically located at the front or underneath the glove box and can be adjusted or customized to suit the user's needs.e-mail:amy@etelux.com.

The following should be observed when using the glove box foot pedal:

Apply appropriate force to the foot pedal to ensure proper door opening or closing action.

Pay attention to the position and operation of the foot pedal to avoid misuse or unnecessary injury.

Follow the instructions and safety guidelines for the glove box foot pedal to ensure safe and correct operation.

It is important to note that the design and operation of the foot pedal may vary in specific glove box equipment. Therefore, it is best to consult the appropriate equipment manual or contact the equipment manufacturer for accurate information and guidance before operating the glove box foot pedal.

Glove box aparts--- Pneumatic baffle valves

A pneumatic baffle valve (Pneumatic Butterfly Valve) is a pneumatically powered valve used to control flow in a pipeline or fluid system. It consists of a rotating circular baffle and a sealing ring paired with it, which opens or closes the fluid passage by rotating the baffle.

Pneumatic baffle valve has the following main features and functions:

Pneumatic operation: Pneumatic baffle valves use a gas source (usually compressed air) as a power source to control the opening and closing of the valve by adjusting the pressure of the gas source. This pneumatic operation makes the control of the valve more flexible and convenient.

Fast Response: Because the pneumatic flapper valve is pneumatically driven and does not require the involvement of electricity or hydraulics, it has a fast response time. The action of opening or closing the valve can be accomplished in a very short time, providing rapid flow control.

Fluid regulation: Pneumatic baffle valves can realize many different fluid regulation functions, including full open, full close and partial open. By adjusting the angle of the baffle, the speed and flow of fluid through the valve can be precisely controlled to meet specific process requirements.

Sealing performance: Pneumatic baffle valves use sealing rings to ensure a good seal between the valve and the pipeline, thus preventing fluid leakage. The seals are usually made of corrosion-resistant materials and can be adapted to a variety of fluid media and working conditions.

Reliability and Durability: Pneumatic flapper valves are usually manufactured from high-strength and corrosion-resistant materials for good durability and reliability. They are often used in a variety of industrial applications, including chemical, oil, gas, water treatment and food processing.

Pneumatic flapper valves have a wide range of applications in fluid control, and their benefits include flexible operation, fast response, precise flow control and good sealing performance. When selecting and using pneumatic flapper valves, it is necessary to consider factors such as fluid medium, operating pressure, temperature range and pipe size, as well as proper installation, maintenance and overhaul to ensure proper operation and long-term reliability.

Glove box aprts---Main antechamber

The Large Transfer Chamber (LTC) of a glove box is an area within the glove box that is used for the process of transferring items and loading samples between the external and internal environments of the glove box. It is typically a space with a sealed door that allows an operator to bring items into the glovebox from the external environment or to remove items from the glovebox to the external environment.

The primary function of the large transition compartment is to ensure that the isolation of the glove box is maintained during the transfer of items. It typically has the following features:

Sealed Door: the large transition compartment is isolated from the rest of the glove box and is accessed through a sealed door. The opening and closing operation of the sealed door allows for the safe transfer of items while ensuring isolation between the inside and outside of the glove box.

Bi-directional transfer: The large transition compartment allows for bi-directional transfer of items between the inside and outside of the glove box. Operators can place samples or items in or out of the glove box without opening the entire glove box door.

Environmental Control: Large Transition Chambers typically have some degree of environmental control, such as temperature, humidity and atmosphere control, to meet specific experimental or operational requirements.

The design and size of the large transition chamber can vary depending on the specific application and needs. It plays a key role in glove box operations, allowing the operator to perform efficient transfer of items while maintaining sample and environmental isolation. When using the Grand Transition Pod, operators should follow the relevant operating instructions and ensure that the sealed door is used and maintained correctly to ensure glovebox isolation and safe operation.

| Transit Module Hull | Dimensions | Diameter 360mm, Length 600mm (Optional Diameter 390mm) |

| Material | 304 stainless steel | |

| Surface | Brushed internal surface, painted external surface | |

| Accessories | Tray | Stainless steel mirror finish, sliding tray |

| Hatches | Double door, anodized aluminum, with power lifting mechanism | |

| Pressure gauge | Wika vacuum oil gauge or digital display | |

| Control | Operation | PLC control or manual operation |

Of course, for more details, we offer customized square, round and other sizes on our website. If you have any need,please contact me by a-mail:amy@etelux.com

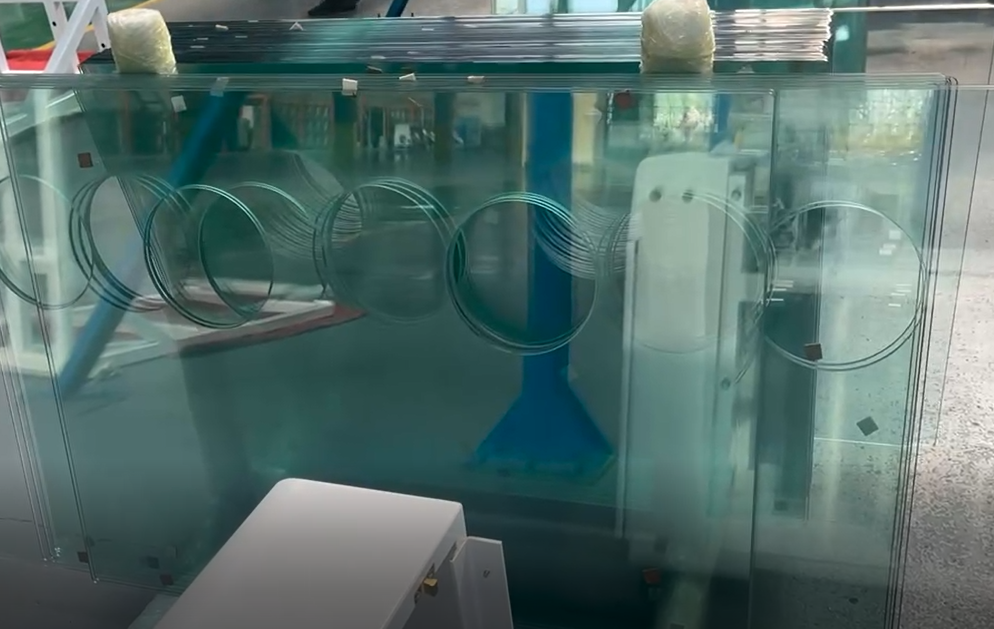

Glove box parts---Glass

Acrylic is often referred to as "acrylic window glass" because it is similar to glass in appearanceand transparency, but differs greatly from glass in its chemical composition and physical properties.

Acrylic (polymethylmethacrylate, PMMA) is a polymer material made by polymerizing methyl methacrylate monomer. Compared to glass, acrylic has better impact resistance, lighter weight, higher light transmission and better weather resistance. It is widely used in many fields, such as construction, home decoration, advertising, display equipment and so on.

Acrylic material (PMMA), as a plastic material that replaces glass, has the following advantages and disadvantages:

Advantages:

High transparency, similar to ordinary glass;

Good impact resistance, more impact resistant than glass in the same thickness, not easy to break;

Good UV protection, more difficult to fade and turn yellow than glass;

Strong processability, can be manufactured into different shapes by injection molding, extrusion or molding and other ways;

Compared to glass, acrylic is lightweight, making it easy to handle and install.

The front window glass of Nichwell glove boxes is usually made of acrylic (PMMA). Acrylic is a transparent plastic material with high chemical and impact resistance. It is widely used in many laboratory and industrial applications because it provides good visibility and is relatively lightweight. Acrylic also has excellent weathering and UV resistance and is not prone to yellowing or brittleness.

Glove box parts---moisture transmitter

The moisture transmitter is an important component used in glove boxes to detect the presence or level of water or other liquids. It plays a critical role in maintaining a controlled environment and protecting sensitive materials or equipment from potential damage caused by moisture.

Read More

Glove box application -----display manufacturing

Generally speaking, the manufacture of displays requires a dust-free environment, and the dust-free environment will involve a glove box products - 100 purification glove box

Hundred clean glove box is a set of high-performance, high-quality automatic absorption of water, oxygen molecules, super purification glove box, to provide a clean working environment needs of the closed loop working system, can meet your specific clean requirements, O2 and H2O ≤ 1ppm inert gas protection environment. The system is designed to meet the customer's scientific research and development of economical circulation purification system and FFU glove box, the fan from the top of the FFU, the gas will be sucked in and filtered by the primary and high efficiency filters of clean gas sent back to the box (closed loop).

Product features Simple: manufactured in strict accordance with German technology standards, operated by Siemens 7-inch touch screen, the operation interface is simple and easy to start. Safety: modular design, professional no-leakage sealing technology, ultra-low leakage rate of ≤ 0.001%, (industry standard ≤ 0.050%), strictly according to the standard "EJ_T1096_1999_Sealing chamber sealing classification and its test methods" in the first class sealing chamber acceptance.

Facility Requirements for Glove Box Products

Glove box products are highly sophisticated and sensitive equipment used in industries such as pharmaceuticals, electronics, and chemical research to provide a controlled environment for handling sensitive materials. To ensure the optimal functionality and performance of these products, certain facility requirements must be met. This article aims to outline the key facility requirements for glove box products.

Space Requirements: The first requirement for installing a glove box product is adequate space. The size of the glove box will depend on the specific application and the user's requirements. Depending on the application, the glove boxes can range from small benchtop models to large walk-in units. Ensure that there is sufficient space available to accommodate the glove box and associated equipment.

Electrical Requirements: Most glove box products require electrical power to operate the blower, lights, temperature controls, and other components. Ensure that the facility has appropriate electrical outlets, wiring, and circuit breakers to support the glove box's electrical needs. Consult the manufacturer's instructions for specific electrical requirements for your glove box model.

HVAC Requirements: Glove boxes require a controlled environment with respect to temperature, humidity, and air quality. Therefore, heating, ventilation, and air conditioning (HVAC) systems should be adequate for the glove box's specific application. The HVAC system should maintain the required temperature range for the glove box and prevent any significant temperature fluctuations.

Gas Supply: Glove boxes usually require an inert gas supply, such as nitrogen or argon, to establish and maintain an inert atmosphere inside the glove box. Ensure that the facility has a reliable and adequate gas supply to support the glove box's specific gas requirements. The supply lines should be clean and free of contaminants to prevent any contamination of the glove box environment.

Flooring and Footing: Ensure that the floor where the glove box is installed is level, stable, and capable of supporting the weight of the glove box, associated equipment, and occupants. Some glove boxes may require a foundation or reinforced flooring to provide additional stability. The footing should also be capable of absorbing any vibrations from nearby machinery or equipment that may affect the glove box.

Lighting: Proper lighting is essential for the user to see inside the glove box chamber. Adequate and uniform lighting should be installed inside the glove box, and external light sources should not interfere with the user's visibility. Avoid direct sunlight on the glove box, as it may cause unwanted heating and temperature fluctuations.

Accessibility: Ensure that the glove box product is accessible for maintenance and cleaning tasks. Adequate space around the glove box should be available for easy access to all sides, including the back, and servicing the glove box's components. Ensure that there is sufficient clearance for the user to move in and out of the glove box without any discomfort.

Safety and Health Requirements: Maintain strict safety and health standards when installing and operating glove box products. Ensure that proper ventilation is provided, and appropriate personal protective equipment (PPE) is used during installation, operation, and maintenance tasks. All necessary safety procedures and protocols should be maintained and followed regularly.

In conclusion, the facility requirements for glove box products are critical for ensuring proper installation, operation, and maintenance. Proper space, electrical outlets, HVAC systems, gas supply, flooring, lighting, accessibility, and safety and health standards are necessary for optimal performance and user safety. Always refer to the manufacturer's instructions and guidelines for specific facility requirements for your glove box model.

Daily Maintenance of Glove Boxes

For daily scientific experiments, the glove box provides a safe environment is particularly important; through the cycle, purification, regeneration and other links have provided important protection; then as a protective device for experiments, in addition to understanding its use, how to carry out routine maintenance is also very important, today we will explain the daily protection of the glove box:

1.Exterior Cleaning: Wipe down the external surfaces of the glove box using a mild detergent or cleaning solution and a soft cloth or sponge. Ensure that the cleaning solution does not damage the material of the glove box. Rinse with clean water and dry thoroughly.

2. Interior Cleaning: Clean the interior surfaces of the glove box using a mild cleaning solution recommended by the manufacturer. Pay special attention to areas prone to contamination, such as the work surface, gloves, windows, and transfer chambers. Use lint-free wipes or swabs to remove any particulate matter or residues. Rinse with clean water and dry thoroughly.

3. Glove Cleaning: Clean the gloves regularly using a mild soap solution. Gently scrub the gloves and rinse with clean water. Ensure that the gloves are completely dry before use.

4、Oxygen and Moisture Levels: Monitor the oxygen and moisture levels inside the glove box using appropriate sensors or meters. Ensure that the levels are within the specified range. If any deviations are observed, troubleshoot the issue or contact the manufacturer for assistance.

5. Pressure Monitoring: Regularly check and record the pressure inside the glove box using a pressure gauge or sensor. Maintain the pressure at the recommended level to ensure the desired working conditions.

6. Gas Purification System: If the glove box is equipped with a gas purification system, monitor and maintain it as per the manufacturer's instructions. Replace or regenerate the purification materials as necessary to ensure optimal performance.

7.User Training:Ensure that all personnel who operate the glove box are adequately trained in its proper use and maintenance. Provide training on handling sensitive materials, following protocols, and maintaining the glove box's cleanliness.

8. Record the water and oxygen content of the glove box and the gas consumption of the equipment carefully every day, so as to avoid insufficient gas pressure, which will cause the equipment to stop running

9.In case of power failure, press the "vacuum pump" button on the panel to make the vacuum pump run after power on.

10. When you want to put the sample into the glove box, try to use the small transition chamber, and before you open the door of the transition chamber, you need to pay attention to whether the pressure gauge pointer on the valve chamber is in the zero position. If yes, you can open it directly; if not, you need to turn the switch under the valve chamber to the "fill" position, so that the gas into the glove box transition chamber, and then turn the switch back to the center position, at this time you can open the transition chamber door to put the sample in, and then close the door. When placing samples, be careful not to touch the inner wall of the transition chamber with your hands, and wear gloves when placing samples.

11. When using the equipment, it is forbidden to wear watches, rings and other things that may puncture the gloves, and if you use sharp objects, you should pay extra attention in order to avoid puncturing the gloves, and there is a chance that your fingernails are too long and may puncture the gloves.

12. box and glass with commonly used cleaning agents to clean the outside (prohibit the use of corrosive cleaning agents); with a soft, lint-free cloth; if possible to use a vacuum cleaner with a brush or sticky paper roller.

13.Check whether the transition hatch seals are broken or not, and replace the broken seals in time. If the transition hatch is difficult to open or close, if it is a mechanical problem to be solved after consulting us, if the seal problem, you can apply less grease or lubricant to try.

Operating Manual for Vacuum Glove Box

Vacuum glove boxes are widely used in industries with high requirements for gas purification. But the vacuum glove box structure is complex, many important parts, the operation of a little improper, may cause damage to your experimental results. This article introduces you, how to properly use the vacuum glove box, as well as novice operation of the glove box when the precautions.